Fundamentals of DTH Drill Rig Efficiency in Hard Rock Drilling

The Down-The-Hole or DTH hammer works best when three main factors work together properly: the power from the drill rig itself, the compressed air pressure inside the system, and those adjustable settings controlled by the operator like feed force adjustments. Most modern DTH setups need around 350 to 500 psi of air pressure according to research published in the International Journal of Rock Mechanics back in 2024. This level helps create enough impact energy for tough rocks like granite and quartzite. When it comes to basalt formations, we've seen that increasing the power output actually makes things go faster too about 22 to 28 percent improvement in penetration speed compared to lower power settings.

Key factors affecting DTH hammer efficiency: Drill rig power, air pressure, and operating parameters

Getting the right setup for a DTH drill rig means finding the sweet spot between hydraulic power (usually around 150 to 300 HP) and what the air compressor can handle. From actual field experience, keeping airflow between 4.5 and 6 cubic meters per minute at about 500 psi pressure makes those bits last roughly 40% longer when drilling through really rough, abrasive rock formations compared to setups that aren't quite right. Experienced operators know they need to tweak both feed pressure and how fast the drill spins depending on what they're feeling from the ground below. This helps save fuel money and keeps the equipment from wearing out too quickly during tough jobs.

Performance metrics: Impact energy, frequency, and power output in high-impact DTH systems

Today's high impact DTH hammers pack quite a punch, delivering anywhere from around 2000 to almost 4500 joules per blow while hitting rocks at rates above 1800 strikes per minute. The Rock Drilling Research Institute published findings last year showing that when these machines run at about 3200 joules combined with those 1800 spm figures, they actually last 35 percent longer before needing maintenance work. What makes this possible? Well, power output really tells us how efficiently energy gets transferred during drilling operations. Some of the best models on the market today manage to convert more than 78% of their input energy directly into breaking apart rock formations, which is pretty impressive considering all the losses that typically occur in mechanical systems.

Quantifying drilling efficiency: The relationship between impact energy and penetration rate

The way rocks break down when drilling gets faster as we pump more energy into the system follows something like a logarithmic curve. For every extra 10% of energy applied, drill bits generally move through hard rock about 6 to 8% quicker. Field tests conducted last year revealed some impressive results too. When engineers fine-tuned their Down-The-Hole hammer setups, they saw these specialized drills punch through metamorphic rock at speeds around 40% better than standard rotary techniques according to recent studies from Rock Drilling Research Institute. Given this performance boost, it's no wonder why many contractors now consider DTH tech indispensable for boring holes deeper than 100 meters where rock formations typically have compression strengths above 250 megapascals. The savings in time alone justify the investment for most operations working in tough geological conditions.

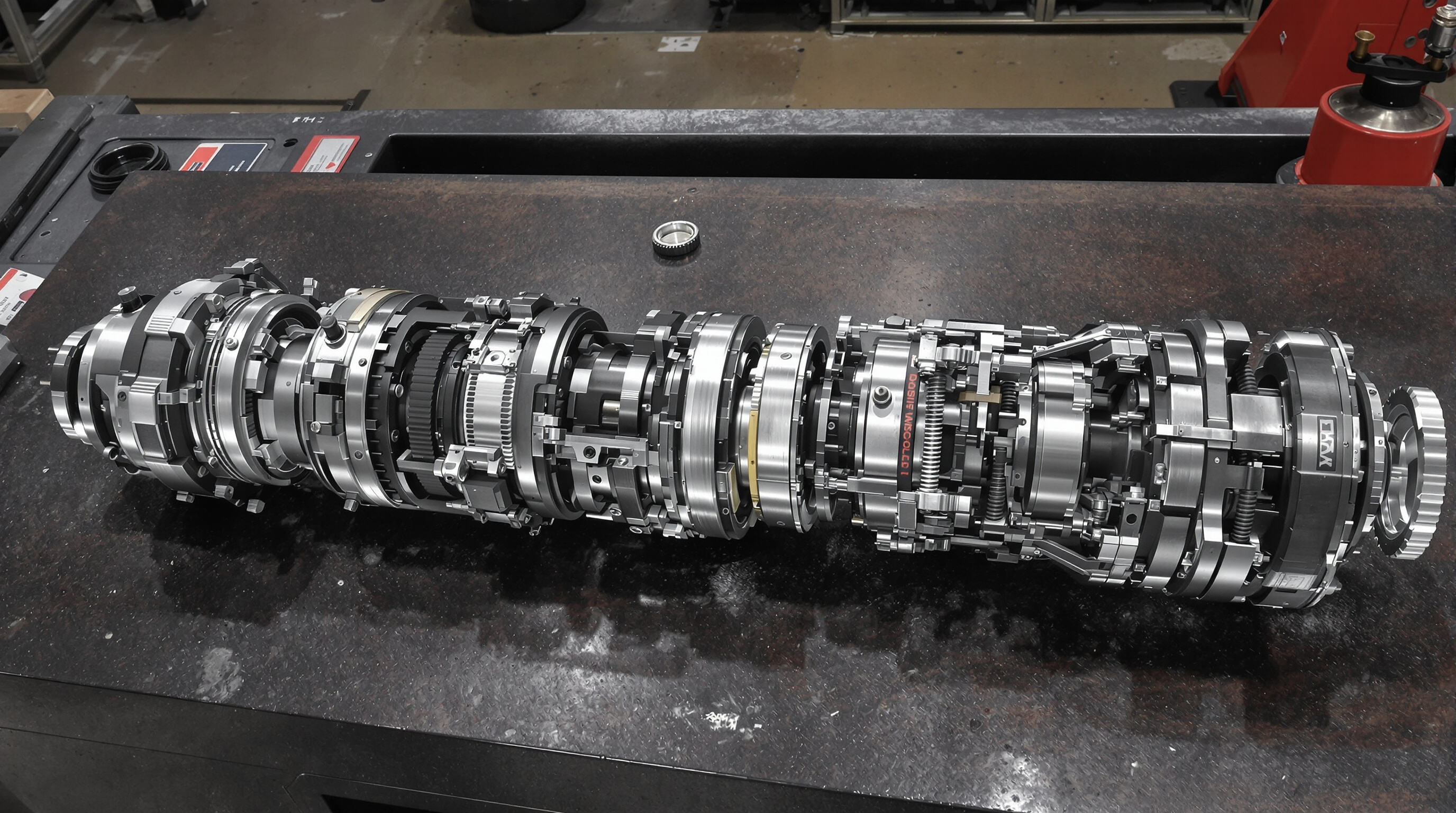

Core Engineering Design of High-Performance DTH Hammer Systems

Design Principles for Durability Under Extreme Impact and Abrasive Conditions

High-performance DTH hammer systems are engineered to withstand sustained forces over 25 kN and resist abrasive wear from rock particulates. Key design features include:

- Carbide-alloy components in pistons and valves to prevent deformation under repeated impacts

- Multi-stage heat treatment (e.g., austempering), improving fatigue resistance by 30—50% in hammer bodies

- Labyrinth sealing systems that block fine silica particles from entering moving parts

A 2023 industry study found optimized DTH designs reduce component replacement frequency by 40% during granite drilling compared to conventional models.

Innovations in Fluidic Oscillator Technology and Backward-Impact-Damping Mechanisms

Fluidic oscillators in modern systems convert 95—98% of compressed air energy into productive impact force, surpassing traditional valve designs (75—85%). Backward-impact-damping mechanisms manage residual shockwaves using:

- Tuned mass dampers dissipating 60—70% of recoil energy

- Elastomer-spring hybrid buffers isolating critical components from vibration harmonics

These innovations support sustained operation at 1,800—2,200 blows per minute without compromising structural integrity.

Case Study: Robust Engineering Approaches in Modern DTH Systems

A leading manufacturer achieved 2,500-hour service intervals in quartzite drilling through three key enhancements:

- Gradient-hardened bit shanks combining Rockwell 58C surface hardness with ductile inner cores

- Phase-synchronized piston arrays maintaining ±2% energy consistency across impact cycles

- Dynamic pressure compensation chambers stabilizing airflow during 100—150 MPa pressure fluctuations

Field trials confirmed 28% higher penetration rates in basalt compared to industry averages, validating these engineering solutions.

Optimizing Impact Energy Transfer: From Mechanism to Real-World Application

Physics of High-Impact Force Generation in DTH Hammer Systems

Down-the-hole hammers work by turning compressed air into mechanical force using a piston inside a cylinder. When these tools reach maximum output, they can produce impacts over 25 kilonewtons in bursts lasting less than 20 milliseconds according to research published in the International Journal of Rock Mechanics last year. How well energy moves through the system really affects how effective it is overall. Newer models manage to keep around 68 to 72 percent of their energy intact thanks to better designed ratios between the piston weight and drill bit mass. This helps reduce what gets lost as unwanted vibrations and heat during operation.

Efficient Energy Transfer: Optimizing the Hammer-Bit-Rock Interface

Three factors govern energy transfer at the interface:

- Bit shank geometry matching hammer driver dimensions within ±0.05 mm tolerance

- Tungsten-carbide inserts arranged in double-cone patterns for even stress distribution

- Shock-absorbing polymer buffers reducing reflected stress waves by 40%

Field tests show tapered bit designs improve energy coupling by 18% in basalt compared to flat-face alternatives (Drilling Equipment Quarterly, 2023). Leading manufacturers now use real-time impedance matching systems that adjust impact frequency based on rock hardness sensors.

Field Measurement of Impact Energy Delivery in Granite, Basalt, and Quartzite Formations

Recent comparative studies reveal notable performance differences:

| Rock Type | Measured Impact Energy (kJ) | Penetration Rate (m/h) |

|---|---|---|

| Granite | 1,820 ± 110 | 4.2—5.7 |

| Basalt | 2,150 ± 90 | 6.1—7.4 |

| Quartzite | 1,950 ± 130 | 3.8—4.9 |

These results underscore the need for adaptive DTH configurations, especially in mixed lithology sites where energy delivery varies by over 30% within a single borehole. Advanced telemetry enables operators to maintain ±5% energy consistency through automated pressure compensation.

Advanced Drill Bit Technology for Maximum DTH Hammer Performance

Innovative Materials and Geometries in Drill Bit Design for Hard, Abrasive Rock

Modern DTH performance relies on drill bits combining advanced carbide composites (85—92 HRA hardness) with optimized geometries such as semi-spherical buttons and asymmetric flute patterns. Bits with graded tungsten carbide inserts and hexagonal button layouts achieve 18—23% higher penetration in quartzite than standard designs (International Drilling Journal, 2023). Key advancements include:

- Multi-stage wear-resistant coatings extending bit life by 40% in basalt

- 3D-printed cooling channels reducing thermal degradation by 32% at 1,200+ psi

- Synthetic diamond matrices for granite with compressive strength over 280 MPa

Matching Bit Selection to Rock Hardness and Formation Characteristics

Optimal performance requires aligning button impact angles (90°—120°) and flushing port configurations with geological conditions:

| Rock Type | Recommended Bit Features | Penetration Rate Improvement |

|---|---|---|

| Fractured Granite | 13mm concave buttons, 6-port asymmetric flow | 27% vs flat-face designs |

| Massive Basalt | 16mm spherical buttons, turbo-flush channels | 33% vs standard geometries |

| Abrasive Sandstone | Dual-hardness inserts, chrome-nitride coating | 41% wear resistance boost |

Proper bit-rock matching reduces component stress by 19% (Geotechnical Drilling Association, 2023) while sustaining 0.8—1.2 m/min penetration rates in extreme formations.

Applications and Operational Challenges in Modern Hard Rock Drilling

Advantages of DTH Hammers in High-Efficiency, Deep-Hole Hard Rock Drilling

Direct action hammer technology gets about 20 to maybe even 30 percent better results when drilling through hard materials like granite and basalt compared with older techniques because all the energy goes straight into breaking the rock where the bit meets the surface. According to recent market research published last year, these improved DTH systems can cut down on hole wandering by nearly half in really deep drill sites over 300 meters down. The rapid pounding action between 1200 and 1800 hits per minute breaks apart rocks effectively without creating much heat buildup, which means the tools last longer when working on extended projects. This efficiency makes a big difference in real world conditions where downtime costs money and precision matters.

Balancing High Impact Energy With Component Wear: The Industry’s Key Durability Challenge

Drilling gets faster when impact forces go over 50 kN, but comes at a price. The equipment starts wearing out quicker, especially those pistons and bit shanks take a real beating. Research from last year showed something interesting too. For every 10% bump in impact energy, maintenance bills jump around $18 to $25 extra each hour just because parts need replacing so often. Smart companies tackle this problem in two main ways. They install tungsten carbide inserts which last about three times longer than regular steel against all that grinding action. Some also use fancy pressure control systems that adjust how hard it hits depending on what kind of rock is being drilled through right now.

FAQ

What is a DTH hammer?

A DTH (Down-The-Hole) hammer is a drilling tool that uses compressed air to drive a piston inside a hammer to transmit repeated impact energy directly to a drill bit. It's highly effective for drilling in hard rock formations.

How does impact energy affect drilling efficiency?

The rate at which rock breaks down increases as more energy is introduced into the system. For every 10% additional energy, there is typically a 6-8% increase in penetration rate, allowing faster drilling through hard rock.

What are the main challenges in using DTH hammers?

The primary challenges include managing the wear on components due to high impact forces and optimizing energy transfer to improve drilling efficiency while maintaining durability.

How can DTH hammer performance be optimized?

Performance can be optimized by fine-tuning operating parameters such as feed pressure, selecting suitable drill bit designs for specific rock types, and using advanced technologies like fluidic oscillators and impact-damping mechanisms.

Table of Contents

- Fundamentals of DTH Drill Rig Efficiency in Hard Rock Drilling

- Core Engineering Design of High-Performance DTH Hammer Systems

- Optimizing Impact Energy Transfer: From Mechanism to Real-World Application

- Advanced Drill Bit Technology for Maximum DTH Hammer Performance

- Applications and Operational Challenges in Modern Hard Rock Drilling

- FAQ