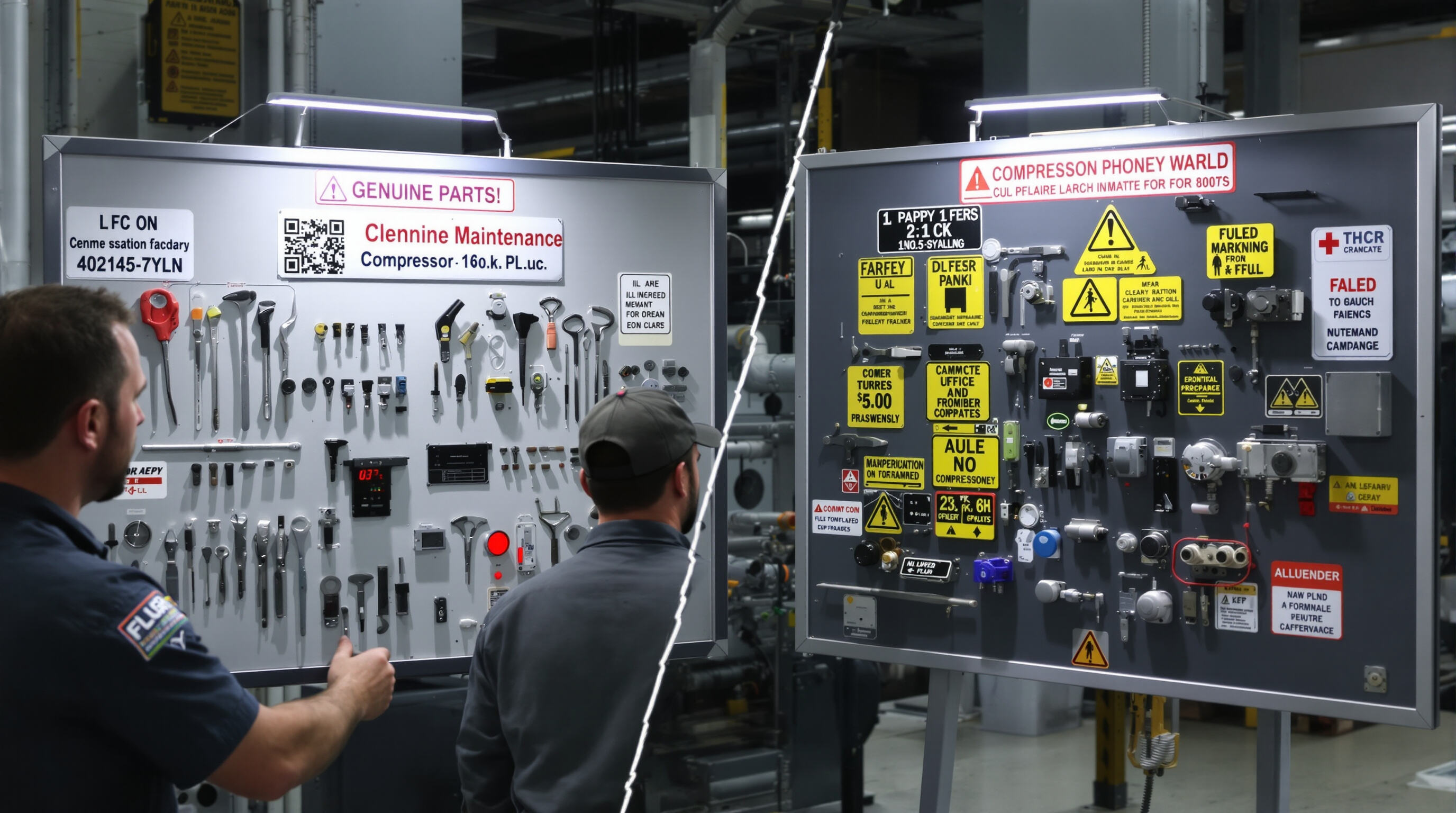

Understanding OEM vs. Aftermarket Parts in Screw Air Compressors

How Part Origin Impacts System Integrity and Performance

Parts made by OEMs (Original Equipment Manufacturers) for screw air compressors are built specifically for each system, which helps them perform better and last longer. According to field tests, compressors with genuine OEM parts can keep around 97% volumetric efficiency after running for 5,000 hours, while those with cheaper aftermarket parts drop down to about 82%. The difference comes down to how tight everything fits together in OEM parts like rotors, seals, and bearings. Small differences here mess with airflow and actually make vibrations worse by anywhere from 18% to 32%, according to the Industrial Compressor Reliability Report from 2023. Generic parts usually miss out on special material treatments that OEMs apply, so these cheaper options tend to wear down faster at important contact points where components touch each other.

Growing Use of Aftermarket Components in Industrial Maintenance

A lot of maintenance crews still go for those cheaper aftermarket compressor parts even though there are performance risks involved. About 64 percent of them do this mainly because these parts are less expensive and easier to get hold of when needed. Most often we see filters replaced along with gaskets and those coupling guards too. Facilities tend to care more about getting things fixed within 48 hours rather than going for exact replacements. But there's a catch here worth mentioning. Studies show around 23% of all compressor breakdowns connected to these aftermarket components actually come from problems that weren't obvious at first glance. Take oil contamination for instance which happens quite frequently because some of these cheaper filters just don't cut it compared to original equipment.

Evaluating When to Choose Genuine vs. Aftermarket Parts

Key decision factors include:

- Warranty Status: 89% of OEM warranties are voided if aftermarket parts contribute to system failure

- Failure Criticality: Genuine components are essential for pressure valves, rotor assemblies, and thermal management systems

- Total Cost: Aftermarket air filters cost 40% less upfront, but their shorter lifespan increases annual replacement labor by 21%

For non-production-critical applications or legacy systems, certified aftermarket parts meeting ISO 1217:2021 air-end standards can offer reliable, cost-effective solutions without compromising safety.

Performance and Reliability: Why Kaishan Genuine Parts Matter

Impact of Aftermarket Parts on Compression Efficiency

Non-OEM components reduce compression efficiency by 12–18% compared to genuine parts, according to 2023 industry benchmarks. Inaccurate manufacturing tolerances in aftermarket valve plates and rotor profiles compromise air sealing during compression cycles, directly affecting output and energy use.

Long-Term Durability: Field Data from Real-World Operations

A five-year study across 87 industrial sites found compressors using genuine Kaishan parts required 37% fewer unplanned maintenance interventions. OEM-designed bearings maintained proper shaft alignment 2.8 times longer than aftermarket versions, significantly reducing vibration-related failures and extending service life.

Are Aftermarket Manufacturers Closing the Quality Gap?

While third-party producers have improved surface treatments for wear components like cylinder liners, key performance gaps persist. Teardown analyses reveal aftermarket air-oil separators average 23% lower particulate retention than OEM filters, increasing contamination risks and shortening oil life.

Warranty, Support, and Operational Risks of Non-OEM Components

Industrial operators using aftermarket parts in screw air compressors risk undermining system safeguards and long-term value. While non-OEM components may offer initial savings, they introduce operational vulnerabilities that affect warranty coverage, technical support, and reliability.

How Non-OEM Parts Affect Kaishan Warranty Coverage

The Kaishan warranty only stays in effect if genuine OEM parts are used throughout. According to industry reports, around three quarters of equipment makers will completely cancel their warranties if problems arise from third party components. Take rotors as just one case study. Aftermarket ones that aren't quite within specification tolerances often result in bearing alignment issues down the road. Fixing these kinds of problems typically runs somewhere between $3500 and $5000 depending on location and shop rates. Most technicians label this kind of damage as preventable whenever non original parts were installed in the first place.

Maintenance Risks and Long-Term Service Implications

Textile plant operators report that compressors fitted with aftermarket valves need almost half again as much unplanned maintenance compared to those with original manufacturer parts. Most problems stem from mismatched seals and gaskets, which make up around two thirds of all failures. These faulty components create air leaks that cut system efficiency somewhere between 12 and 18 percent. While it's true that buying non-OEM parts saves money upfront (typically 30 to 50 percent cheaper), the reality is quite different when considering lost production time and shorter equipment life. The initial savings usually disappear completely within just two to three years of operation according to maintenance records across the industry.

Total Cost of Ownership: Balancing Upfront Savings and Long-Term Value

Upfront Cost Differences Between Genuine and Aftermarket Parts

Genuine screw air compressor parts typically cost 20–35% more than aftermarket options. However, industrial maintenance teams report an 18% higher failure rate with aftermarket valve plates and rotors within the first year, offsetting initial savings.

How Part Quality Influences Downtime and Equipment Lifespan

A 2023 study of 47 manufacturing plants found compressors with OEM-grade components operated 12% more efficiently between service intervals. Key findings include:

- Energy consumption: Aftermarket air filters increased power draw by 9%

- Unplanned downtime: 29% higher with non-genuine parts

- Component lifespan: OEM rotor assemblies lasted 2.1 years versus 1.4 years for aftermarket equivalents

5-Year Cost-Effectiveness Analysis of Genuine Kaishan Components

Over a five-year period, genuine parts deliver 24% lower total cost of ownership. Field data highlights the cumulative impact:

| Cost Factor | Genuine Parts | Aftermarket |

|---|---|---|

| Initial Purchase | $18,400 | $12,750 |

| Maintenance Labor | $9,200 | $14,100 |

| Energy Consumption | $58,300 | $63,900 |

| Downtime Losses | $6,500 | $22,400 |

The total savings of $360,000 per system with OEM components stem from sustained efficiency and fewer service events, confirming long-term value outweighs short-term price advantages.

FAQ

What are OEM parts?

OEM parts are components made by the Original Equipment Manufacturer, designed to fit perfectly and maintain high performance in a specific system.

Why do some facilities use aftermarket parts?

Many facilities opt for aftermarket parts because they are cheaper and more accessible, despite potential performance risks.

How do aftermarket parts affect warranties?

Using aftermarket parts can void OEM warranties, as nearly 89% of warranties are voided if these parts cause system failure.

What are the long-term cost implications of using aftermarket parts?

While aftermarket parts save money upfront, they can increase long-term costs due to higher failure rates, increased maintenance, and associated downtime.

Are there standards that aftermarket parts must meet?

Yes, some certified aftermarket parts meet ISO 1217:2021 air-end standards, which can make them a reliable option for non-critical applications.